Affordable litho printing Solutions for Your Business

A Comprehensive Overview to Comprehending Litho Printing Strategies

The world of litho printing, a strategy originating from the late 18th century, is an interesting mix of history, art, technology and science. Remain with us as we trip right into the fascinating world of litho printing.

The Historical Advancement of Litho Printing

The historic trajectory of litho printing, an essential development in the realm of communication, is a captivating story of human resourcefulness. The process advanced with the arrival of the rotary press, which greatly increased efficiency. Each phase of litho printing's advancement showcases humankind's relentless quest of effectiveness and quality in visual interaction.

Decoding the Science Behind Litho Printing Inks

Relocating forward in the expedition of litho printing strategies, the focus now shifts to the scientific research behind litho printing inks. The structure of these inks, their drying process, and shade mixing strategies develop the foundation of this complicated art type. Comprehending these components is crucial to mastering the craft and attaining the preferred print outcomes.

Structure of Litho Inks

In lithographic printing, the fundamental function of litho inks can not be overemphasized. Pigments, the color-providing components, are carefully ground fragments put on hold in the vehicle, a liquid that lugs the pigment onto the printing surface. Each part plays a critical component in the final print's high quality, making the specific formula of litho inks a complex scientific research.

Ink Drying Refine

From the composition of litho inks, attention transforms to the interesting procedure of ink drying. Two primary approaches are utilized in litho printing: oxidative drying and absorption. Absorption, on the various other hand, involves the ink seeping right into the paper fibers, which is a quicker process yet can lead to much less vivid shades.

Color Combining Strategies

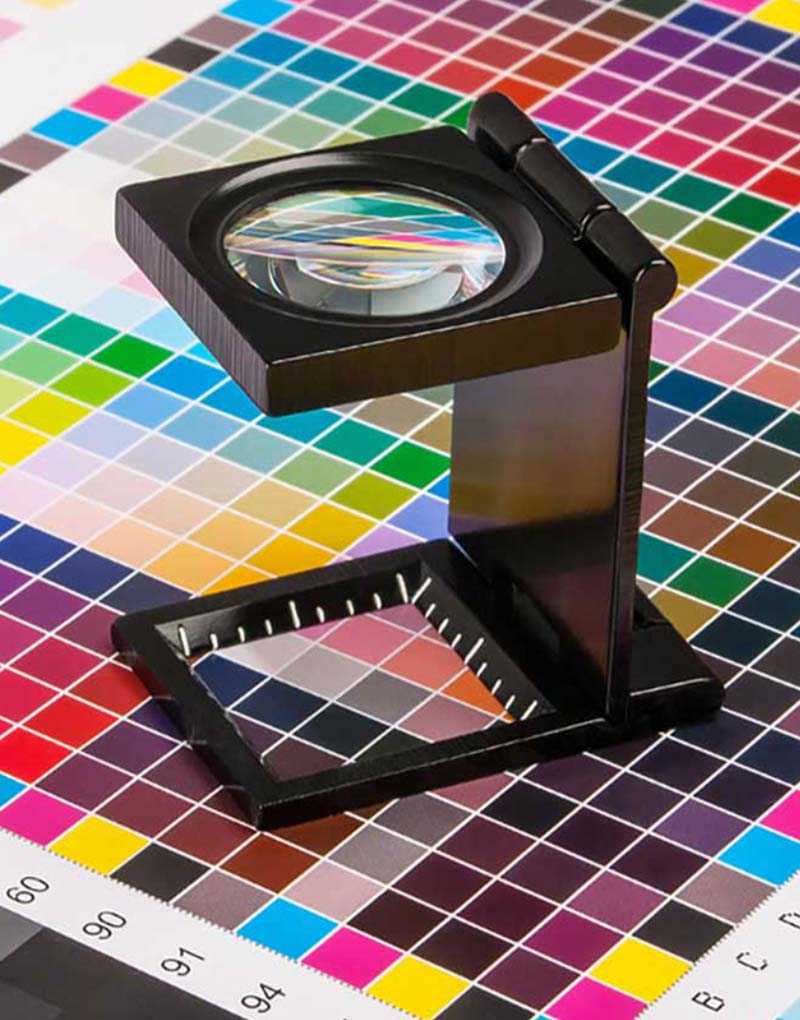

While the drying out process plays a vital duty in litho printing, the science of shade blending techniques holds equivalent relevance. This is a complicated process that entails the cautious mixing of primaries: cyan, magenta, and yellow, in differing proportions to attain a large range of shades. The addition of black ink, called 'vital', helps in managing the intensity and deepness of the colors. The scientific research behind litho printing inks also takes right into account the transparency of the ink, which impacts how shades overlay and mix. To achieve an efficient color mix, print experts must likewise understand the details of ink behavior, shade theory, and the physical homes of the substratum on which the ink is applied.

The Art and Style Components in Litho Printing

Litho printing breathes life right into art and design through its special elements. The procedure involves developing an image on a lithographic sedimentary rock plate or metal plate with a smooth surface area. The image is after that published onto a tool, typically paper, by transferring the ink from home plate. What collections litho publishing apart is its ability to duplicate detailed designs with high fidelity, making the outcome nearly similar to the original artwork. This is accomplished through using different line techniques such as stippling, hatching, and cross-hatching, which enable a series of tonal results. Additionally, litho printing fits a range of shades, making it possible for artists to produce vibrant and dynamic prints. This combination of precision and adaptability makes litho printing a preferred option for many musicians and designers.

Modern Applications of Litho Printing Strategies

Litho printing strategies have actually discovered substantial use in the modern commercial industry. Its this article impact and relevance continue to expand with the arrival of brand-new innovations and modern technologies in the area. This section will certainly discover these modern applications and the transformative duty they play in the printing sector.

Commercial Litho Printing Makes Use Of

In today's electronic age, one might ask yourself about the relevance of typical printing techniques. Yet, litho printing remains a vital component my explanation of the commercial sector. High-volume printing tasks, such as the manufacturing of publications, papers, and packaging, depend on litho printing for its capacity to deliver exceptional image high quality and cost effectiveness. The process, which includes transferring an inked image from a plate onto a rubber covering and after that to the printing surface area, offers unparalleled consistency. This makes it excellent for work needing a big print run. Litho printing also supplies a broad color range, premium to that of digital printing. This makes it the go-to option for tasks that require lively, top notch color recreation.

Technologies in Litho Printing

Pressing the limits of traditional strategies, modern-day developments have actually fueled a host of innovations in litho printing. One famous advancement is electronic litho printing, which incorporates the virtues of digital innovation with litho's premium outcome. These developments underscore the long-lasting significance of litho printing in the modern-day world.

Discovering the Process of Litho Printing: Step by Action

Difficulties and Solutions in Contemporary Litho Printing

Regardless of the precision and practice that litho printing happily upholds, it is not without its collection of contemporary obstacles. One of the most prevalent issues include the high initial configuration expense, difficulty in printing variable information, and ecological issues as a result of chemical usage. Nonetheless, remedies are arising as technology develops. Digital litho printing permits for cost-effective short runs and easy personalization, resolving the concern of variable data. Environmentally-friendly inks and safer plate-making procedures reduce ecological problems. In addition, innovations in automation have actually lowered labor costs, further democratizing the lithography process. Hence, while there are challenges, the litho printing market is proactively adjusting to fulfill them head-on, guaranteeing its relevance in the future.

Conclusion

To conclude, litho printing, with its abundant background and scientific intricacies, holds a substantial area in the print market. As the overview exposes, it's a synthesis of art and technology, with modern innovations guaranteeing its importance. The industry faces obstacles that call for cutting-edge services, with a focus on automation and sustainability. The future of litho printing depends upon its capability to adapt to these changing demands, verifying its enduring worth in an advancing market.